1. Product Introduction

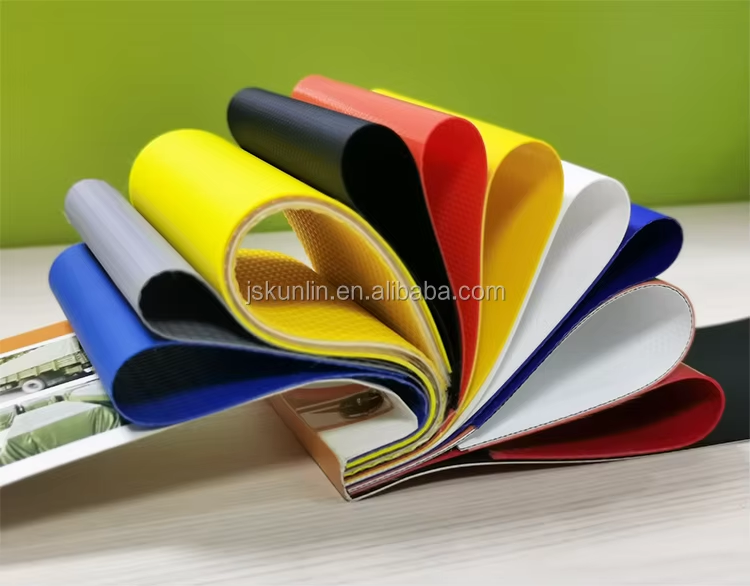

As a project manager overseeing operations across logistics, construction, and agricultural sectors, one of the most consistent challenges lies in ensuring the reliability and durability of protective materials used on-site. Among the wide range of options available today, Stripe PVC Tarpaulin has emerged as a standout solution that combines strength, flexibility, and long-term value. Designed to perform under demanding environmental conditions, Stripe PVC Tarpaulin offers a balance between high tensile strength, full waterproof protection, and cost efficiency — all key parameters in large-scale project management.

In today’s operational environments, temporary coverage structures are no longer just accessories; they are essential components of risk management and resource protection. Stripe PVC Tarpaulin addresses this critical need with a technical structure made from reinforced polyvinyl chloride layers and precision high-frequency heat-sealed seams, ensuring complete resistance to water leakage and weather damage.

From safeguarding stored materials against heavy rainfall to constructing temporary warehouse spaces or covering machinery on agricultural fields, Stripe PVC Tarpaulin provides the reliability that teams require for uninterrupted workflow. Its striped design enhances visibility and identification on large sites, while the material’s coating offers UV resistance and protection against chemical exposure.

In summary, Stripe PVC Tarpaulin represents a new generation of industrial-grade fabric designed not only for coverage but also for cost-effective sustainability. As project managers increasingly look for reusable, eco-conscious materials that align with long-term operational goals, Stripe PVC Tarpaulin has become a preferred choice for enterprises seeking performance, safety, and durability in one integrated solution.

2. Product Features

The engineering of Stripe PVC Tarpaulin focuses on three key pillars: complete waterproofing, flexible deployment, and long-term reusability. Each of these attributes is essential for demanding projects across logistics, construction, and agricultural applications.

1.Complete Waterproof Protection

The first defining feature of Stripe PVC Tarpaulin is its fully waterproof structure. Unlike traditional woven fabrics, this tarpaulin is manufactured with high-frequency heat-sealed seams that eliminate the possibility of water ingress, even under extreme conditions. Tests conducted according to international waterproof standards (ISO 811) show that Stripe PVC Tarpaulin maintains impermeability at pressure levels exceeding 1000 mmH₂O, making it an ideal choice for outdoor exposure. Whether it’s protecting goods in transit, equipment on-site, or produce in agricultural storage, this waterproof integrity ensures operations remain unaffected by adverse weather.

2. Temporary Warehouse and Shelter Construction

Another significant advantage of Stripe PVC Tarpaulin lies in its adaptability for temporary structures. Project sites often require rapid deployment of shelters, workspaces, or storage areas. Stripe PVC Tarpaulin enables the construction of such facilities within hours, not days. The material’s tensile strength supports lightweight steel or aluminum frames, forming stable, weather-resistant enclosures. In logistics terminals, it functions as a rapid-assembly storage tent; in construction, it provides dust and rain shielding; and in agriculture, it serves as a cover for crops or feedstock. Its striped surface design allows for easy visual organization and distinction between different site areas, improving overall operational efficiency.

3. Reusable and Eco-Friendly Design

Unlike disposable covers, Stripe PVC Tarpaulin is engineered for multiple life cycles. The PVC-coated polyester fabric is abrasion-resistant and UV-stabilized, preventing degradation even after extended outdoor use. This translates to a lower total cost of ownership and aligns with global sustainability goals — reducing waste and the frequency of material replacement. Data from field users show that Stripe PVC Tarpaulin can be reused over 30% more times than standard PE tarpaulins, emphasizing its durability and environmental benefit.

4. Strength and Flexibility in Application

Despite its robustness, Stripe PVC Tarpaulin remains flexible and easy to handle. It can be folded, rolled, or welded without losing structural integrity. For project managers, this feature reduces labor time in installation and dismantling, allowing teams to redeploy tarpaulins across multiple job sites. Additionally, the material’s smooth surface makes cleaning simple, minimizing maintenance downtime.

5. Safety and Aesthetic Considerations

The striped pattern of Stripe PVC Tarpaulin provides enhanced visibility, which contributes to workplace safety by marking designated zones or hazardous areas. Beyond functionality, this distinct visual pattern adds an organized, professional appearance to work environments — a subtle but important factor in modern project presentation.

Together, these characteristics make Stripe PVC Tarpaulin not just a material, but a strategic asset that integrates technical reliability with operational efficiency.

3. Application Scenarios

The versatility of Stripe PVC Tarpaulin allows it to serve as a universal solution across multiple industrial and commercial environments.

In Logistics, Stripe PVC Tarpaulin is widely used for cargo protection, truck covers, and temporary storage. The fully waterproof and tear-resistant nature ensures that goods remain safe from rain, dust, or UV exposure during transportation or interim storage. For logistics operators, this product minimizes the risk of shipment damage, thereby enhancing overall supply chain reliability.

In Construction, Stripe PVC Tarpaulin plays a crucial role in protecting construction materials, scaffolding, and partially built structures from environmental stress. Its ability to form temporary shelters enables teams to continue work even during inclement weather, ensuring project schedules remain on track. The high strength and reusability of Stripe PVC Tarpaulin mean that it can be employed across multiple projects, offering both economic and environmental advantages.

In Agriculture, Stripe PVC Tarpaulin is essential for crop and equipment protection. It serves as an effective barrier against rainfall and solar radiation, preserving the quality of stored produce and reducing spoilage. Farmers and agricultural cooperatives use Stripe PVC Tarpaulin to build temporary grain shelters, livestock shading areas, and machinery storage covers. Its easy-to-clean surface and long service life contribute to lower maintenance costs and better resource management.

Overall, Stripe PVC Tarpaulin serves as a multifunctional solution bridging the gap between practicality and sustainability. Whether deployed in large-scale logistics hubs, busy construction zones, or expansive agricultural fields, its consistent performance ensures that essential assets remain protected under all circumstances.

4. Case Study: Real-World Project Application

A recent infrastructure project demonstrates the operational value of Stripe PVC Tarpaulin in real-world conditions. As part of a regional logistics expansion, a large temporary warehouse facility was required to store materials and protect machinery during the construction of a transport terminal. The challenge involved high humidity, frequent rainfall, and fluctuating temperatures — conditions that demanded a robust and reusable covering system.

After evaluating multiple material options, the project management team selected Stripe PVC Tarpaulin due to its fully waterproof and heat-sealed structure. Installation was completed within 48 hours, using modular steel framing and tension-fastened tarpaulin panels. The Stripe PVC Tarpaulin provided 100% coverage for over 2,000 square meters of space, maintaining internal dryness even during prolonged storms. Equipment stored under the shelter showed zero corrosion or moisture damage throughout the 6-month construction phase.

The reusability of Stripe PVC Tarpaulin also proved beneficial after project completion. Instead of being discarded, the material was repurposed for a secondary agricultural use — covering hay bales and livestock feeding areas. Field data later showed that the same tarpaulin maintained over 90% of its tensile strength after multiple uses, reinforcing its long-term economic value.

From a project management perspective, Stripe PVC Tarpaulin provided measurable savings in both time and operational costs. The ability to deploy and dismantle structures quickly minimized downtime, while the product’s durability reduced replacement frequency. Additionally, its striped color pattern improved site organization and safety by clearly delineating operational zones.

This case highlights how Stripe PVC Tarpaulin can transition seamlessly between industries — from logistics to agriculture — while maintaining performance integrity. For project managers seeking reliability, adaptability, and sustainability, Stripe PVC Tarpaulin delivers a proven solution that meets modern operational challenges across multiple environments.