I. Background and Industry Context

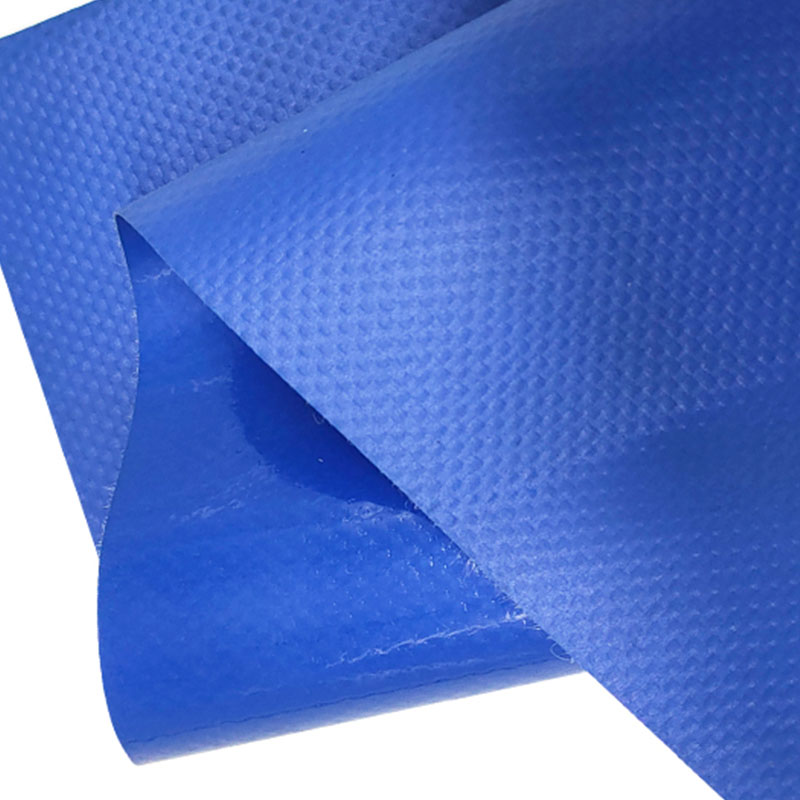

Industrial operations, whether in manufacturing, logistics, agriculture, or construction, require protective covering materials that can endure harsh environmental conditions while maintaining functional reliability. The increasing complexity and scale of modern industrial facilities have amplified the need for durable and versatile tarpaulins, which serve as temporary shelters, equipment covers, cargo protection, and storage enclosures. In this context, pvc tarpaulin has emerged as a leading choice among procurement and operations managers for its combination of durability, maintenance efficiency, and long-term cost-effectiveness.

Traditional tarpaulin materials, such as polyethylene (PE), canvas, or woven fabrics, offer some level of protection; however, their limitations—susceptibility to UV degradation, tearing, water penetration, and surface contamination—often result in frequent replacement cycles. Studies in industrial site maintenance indicate that material failure accounts for nearly 25% of unplanned downtime in outdoor storage environments. As a response, industrial buyers are increasingly evaluating pvc tarpaulin for its enhanced structural engineering, ease of maintenance, and resistance to environmental stressors.

Moreover, the operational advantages of pvc tarpaulin extend beyond mere coverage. The material’s adaptability allows for customized dimensions, reinforced edges, and various coating options, making it suitable for a wide spectrum of industrial applications. Jiangsu Kunlin New Material Technology Co., Ltd. has positioned its pvc tarpaulin product line to meet these evolving requirements, emphasizing durability, long-term protection, and reduced lifecycle cost. For industries with high exposure to weather, mechanical abrasion, or chemical environments, pvc tarpaulin offers a measurable performance advantage over traditional materials.

II. Key Product Features of PVC Tarpaulin

The performance of pvc tarpaulin is closely linked to its engineered material properties, which distinguish it from conventional tarps and coverings. One of the core features is its reinforced joint and edge structure. Industrial-grade pvc tarpaulin typically utilizes multi-layer folding combined with high-temperature heat sealing to strengthen edges and critical stress points. This enhancement prevents common failure modes, such as edge tearing or seam rupture, which are prevalent in cheaper PE or canvas tarps. The edge reinforcement ensures that even when the tarpaulin is stretched under load, the likelihood of material compromise is minimal, providing higher reliability in demanding applications.

Another key characteristic of pvc tarpaulin is its smooth and easy-to-clean surface. Unlike woven or untreated fabric materials, pvc tarpaulin resists dirt adhesion and allows contaminants to be removed simply by rinsing with water. This feature significantly reduces maintenance efforts, an important factor in large-scale industrial operations where cleaning efficiency translates to labor and operational savings. The smooth surface also improves water runoff, preventing pooling that can accelerate material fatigue.

Durability and extended service life are defining benefits of pvc tarpaulin. Its high tensile strength, combined with resistance to UV radiation, moisture, and chemical exposure, allows it to outlast traditional PE tarps by several years. Laboratory and field tests consistently show that industrial-grade pvc tarpaulin maintains structural integrity under prolonged sun exposure and repeated mechanical stress. This longevity not only minimizes replacement frequency but also contributes to lower total cost of ownership for industrial operators.

Finally, pvc tarpaulin can be produced in a wide range of weights, thicknesses, and finishes, allowing customization to specific operational demands. Whether used for heavy-duty cargo covering, temporary shelter construction, or machinery protection, the material’s adaptability ensures reliable performance across multiple industrial scenarios. In sum, the reinforced edges, cleanable surface, and long service life position pvc tarpaulin as a premium solution for industrial protection and covering needs.

III. Comparative Advantages of PVC Tarpaulin over Other Materials

When evaluating industrial tarpaulins, a comparative analysis between pvc tarpaulin and alternative materials—such as polyethylene, canvas, and woven synthetic fabrics—reveals substantial operational benefits. One of the primary advantages of pvc tarpaulin is its structural resilience. While PE tarps may stretch, warp, or develop seam failures under prolonged exposure, pvc tarpaulin retains dimensional stability due to its high tensile strength and reinforced edges. The multi-layer heat-sealed joints prevent tear propagation, allowing pvc tarpaulin to withstand tension, abrasion, and mechanical stress that would quickly degrade conventional coverings.

UV resistance is another critical differentiator. Canvas and untreated woven fabrics degrade rapidly when exposed to direct sunlight, losing flexibility and fading in color. PE tarps are often treated to resist UV radiation, but treatment wears off over time, leading to brittleness. By contrast, pvc tarpaulin incorporates long-lasting UV stabilization, which maintains tensile properties and surface integrity even after months of continuous outdoor exposure. For industrial applications where materials remain outdoors year-round, this extended lifespan directly reduces replacement frequency and associated labor costs.

Maintenance efficiency further separates pvc tarpaulin from other options. The smooth surface of pvc tarpaulin allows dirt, oil, and other contaminants to be removed with minimal effort. Canvas and woven PE tarps often require intensive scrubbing or chemical cleaners, which can accelerate material wear and increase operational overhead. In large-scale industrial settings, the time and labor savings realized by using pvc tarpaulin are significant, contributing to overall operational efficiency.

Waterproofing and chemical resistance also favor pvc tarpaulin. While canvas can absorb moisture, leading to mold and mildew, pvc tarpaulin provides a fully waterproof barrier. Similarly, it resists many industrial chemicals, oils, and solvents, which can degrade other materials. This makes pvc tarpaulin a versatile choice for covering sensitive equipment, raw materials, and bulk goods in industrial environments.

Finally, the total cost of ownership favors pvc tarpaulin despite slightly higher upfront pricing. Its extended durability, reduced maintenance, and resilience to environmental factors mean that over the product lifecycle, pvc tarpaulin offers lower operational costs than PE, canvas, or standard woven tarps. For procurement and operations teams, this translates into a better ROI and fewer disruptions in industrial processes.

In conclusion, compared to conventional tarpaulin materials, pvc tarpaulin provides superior strength, UV resistance, waterproofing, maintenance ease, and long-term cost-effectiveness, making it a preferred choice for demanding industrial applications.

IV. Application Case Study of PVC Tarpaulin

A recent large-scale industrial logistics site illustrates the practical advantages of pvc tarpaulin. The site involved outdoor storage of machinery, raw materials, and pallets exposed to fluctuating weather, dust, and occasional chemical exposure. The management team selected pvc tarpaulin from Jiangsu Kunlin New Material Technology Co., Ltd. to cover high-value equipment and storage stacks.

The reinforced edges and heat-sealed joints of the pvc tarpaulin prevented edge tears when secured with ropes to irregular metal frames. During heavy rainfall, water runoff was efficiently channeled off the smooth surface, keeping the underlying machinery dry and fully operational. The UV-resistant coating maintained color and material flexibility over six months of continuous exposure, outperforming previously used PE tarps.

Maintenance was simplified due to the tarp’s smooth, easy-to-clean surface. Dust accumulation was removed with a hose, without the need for harsh chemicals or labor-intensive scrubbing. This minimized downtime for staff and reduced maintenance costs, demonstrating the efficiency and resilience of pvc tarpaulin in real-world industrial applications.

Conclusion

PVC tarpaulin combines reinforced edge structures, smooth easy-to-clean surfaces, and exceptional durability to provide superior protection in industrial applications. Compared to PE, canvas, or woven fabrics, it offers longer lifespan, UV resistance, waterproofing, chemical tolerance, and reduced maintenance requirements. As demonstrated in logistics and industrial sites, pvc tarpaulin from Jiangsu Kunlin New Material Technology Co., Ltd. delivers measurable operational benefits, lower lifecycle costs, and reliable long-term coverage for demanding industrial environments.